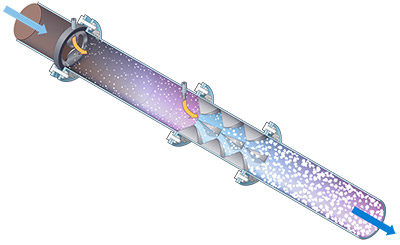

For use in Coagulation/Flocculation applications where suspended solids and particles must be removed from wastewater and space is limited. A coagulant, added to wastewater downstream of Westfall’s Static Mixer Model 2800, undergoes high shear turbulence. Rapid mixing is generated to disperse the coagulant throughout the liquid.

As a result of the coagulant action, charge neutralization occurs and the suspended particles bind together to form larger particles or flocs.

These bonded particles then flow past Westfall’s Low Headloss 3050 vanes for slow and gentle mixing with the polymers required to help the particles form bridges and agglomerate into much larger flocs. Once formed, the large flocs are easily removed by filtration, straining, floatation or sedimentation.

This second stage eliminates the need for lengthy serpentine piping.

Usage and Applications

Poultry Processing Plant

Westfall’s Coagulation/Flocculation device is installed in poultry processing plants in Mexico. The 2 stages can be clearly seen in this video: https://www.youtube.com/watch?v=GBPL_RJD30M. At the end of the second stage, notice the large floccs settling out. And finally see the cleaned wastewater flowing out from the plant.

Replacing Serpentine Piping

In this processing plant, Westfall’s plate mixer 2050 was installed in 2005 to mix coagulants with raw water and charge neutralize suspended solids. Recently the serpentine piping used for the flocculation phase was detached (upper middle) and replaced with Westfall’s pipe mixer 3050 (center). Added polymers are gently mixed to encourage larger flocs prior to removal.

Common Applications

- Municipal Waste Water Treatment

- Industrial Wastewater Cleaning

- Food Processing

- Arsenic Removal

Benefits and Features

| BENEFITS | FEATURES |

|---|---|

| Efficient Treatment in Less Space | Two Mixers in One Pipe |

| Replaces Serpentine Piping | Plate Mixer Produces Small Flocs |

| Increases Settllng Rates | Vane Mixer Encourages Large Flocs |

| Low Maintenance/Low Cost | 1.5 – 120″ Pipe Size |

| Lasts 40-Plus Years |