Designed for Adaptability

A variable flow mixer that allows for more precise control from different wells.

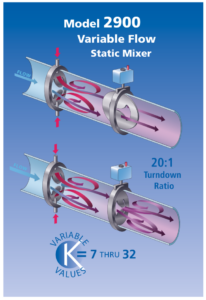

The 2900 Mixer delivers variable flow mixing with minimal headloss

This innovative patented design features two in-line wafer type mixers: one stationary and one mounted on a pivot that adjusts incrementally to changing flow conditions. Each mixing plate’s computer designed, geometric shape creates vortex shedding and shear-induced turbulence inside the pipeline, which effectively mixes the injected fluid(s) with the main process stream.

Providing precise control

Westfall developed a control panel for the system to work with the customer’s software. Flow meters monitor flow and logic boards to signal the mixer to modulate its opening according to flow. When flow is low, the movable mixing plate closes to enhance mixing turbulence, and when flow is high, the plate is wide open to reduce headloss. This maintains optimal mixing for the arsenic removal process, and keeps headloss to a minimum through a 20 to 1 turndown ratio.

The Back Story

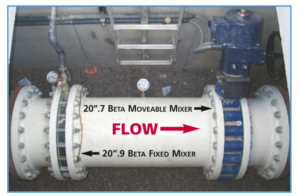

The first Westfall Model 2900 Variable Static Mixer was designed for a water filtration plant in Arizona.The facility had a capacity of 1.2 MGD serving 5,722 customers in a population of 15,000.

There were multiple wells feeding into a water filtration plant, each with a different flow rate ranging from 700 to 7,000 gallons a minute. Any combination of four wells could be used at one time. The objective was to minimize head loss over the entire flow range, and required excellent mixing at very low flow rates for the arsenic removal process. The mixer would facilitate bonding of ferric sulfate with the arsenic that was present, creating bigger particles so the system’s filtration media could filter them out.

The engineer leading the project was familiar with Westfall, as his company had been using Westfall’s Model 2800 Static Wafer Type Mixers routinely for some time. He asked Westfall to solve this new problem, aiming for a maximum of 2 PSI head loss, over as much of the flow range as possible.

They explored solutions together and developed with the project budget in mind. Westfall built a prototype and had it tested at Alden Labs. The data was convincing, and the mixer was manufactured and installed.