Faster Mixing = Shorter Lay Length

Smaller Vaults Cost Less

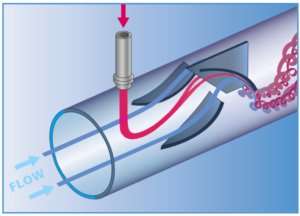

The Westfall engineers are always looking at ways to mix fluids or gases faster and better, using CFD analyses to test and fine-tune our products. We know that when the plan requires a vault for the mixer, smaller is cheaper. Shorter lay length means construction costs can be reduced, so we have designed mixers that accommodate this reality.

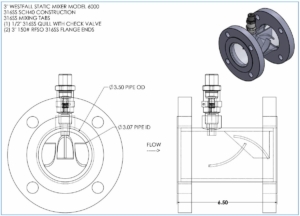

Our Model 6000 provides complete mixing in only 3 diameters. The Model 2800 and the Model 3050 offer appropriate alternatives depending on specific demands of the individual application.

Smaller Vault = Lower Construction Costs

A water supply company in Texas specified a Model 6000 Mixer for its system.

They stated, “The Westfall Model 6000 Static Mixer is an approved alternate static mixer for the chemical feed vault. If the 6000 mixer is selected for the 18” line, the interior length of the chemical feed vault can be reduced from 16′ down to 11′.”

That’s a saving of 5 feet in lay length.

Mixing in 3 Diameters Saves Space

The Model 6000 delivers complete mixing (CoV 0.025 and K-Value of 1.26) within three pipe diameters. It reduces space requirements and saves customers on the cost of additive because of its speed and effectiveness.

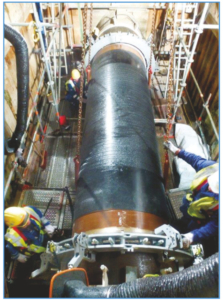

Germany: Local Fabrication

In Germany, we arranged to fabricate and assemble the mixer near the installation site to reduce the need for expensive and time-consuming shipping. This entailed having our engineers communicate and meet with the customer’s supplier to ensure meticulous adherence to the specifications.

We supplied detailed computational fluid dynamics studies, which the customer replicated using their own independent laboratory, thus confirming the effectiveness & longevity they could expect.

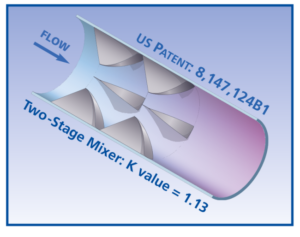

The product was a 48” diameter Westfall Model 3050 Mixer that would blend gas from two different North Sea pipelines having varying densities, compositions, temperatures, and flow rates. The customer required a reliably homogenous mixture for their consumers.

According to Alden Labs, “The Westfall 3050 mixer works quite well in low-head applications provided there are a few pipe diameters available downstream for the flow to mix fully. Since the device was originally designed as a flow conditioner, it is also very effective at mitigating any swirling flow. The low pressure loss characteristics are very desirable for pressure limited operation, and the raked angles prevent fouling.”